Case Studies

Case Study: Reusable Stillage wraps

Client: Multinational Furniture Manufacturer

Region: UK, Europe, USA

Solution by: Palband – Reusable Solutions for Reliable Logistics

Overview

With a huge variety of electrical parts being manufactured in-house, this electrical supplier uses hundreds of metal stillages to transport the parts internally between assembly stations and they we previously using an excessive amount of rolls of plastic pallet wrap to secure the parts inside the stillages.

We designed a bespoke set of stillage wraps which have a unique way of attachment meaning the wrap is always kept as part of the stillage which makes the system extremely easy and efficient to use. The company has a directive from the CEO to constantly find ways to reduce plastic use and this was an excellent way to meet their goals.

- Excessive Plastic Waste: The sheer volume of shrink wrap used on every stillage—across thousands of deliveries—generated a significant amount of single-use plastic waste. This clashed with the company’s growing focus on sustainability and their commitment to reducing environmental impact.

- Inconsistent Application: Shrink wrap was often applied unevenly across sites and by different teams, leading to unpredictable levels of security.

- Product Damage: Inadequate or loose wrapping occasionally allowed heavy boxes to shift during transport. This led to goods arriving damaged or, in some cases, completely unsellable—impacting both customer satisfaction and financial performance.

Our Solution

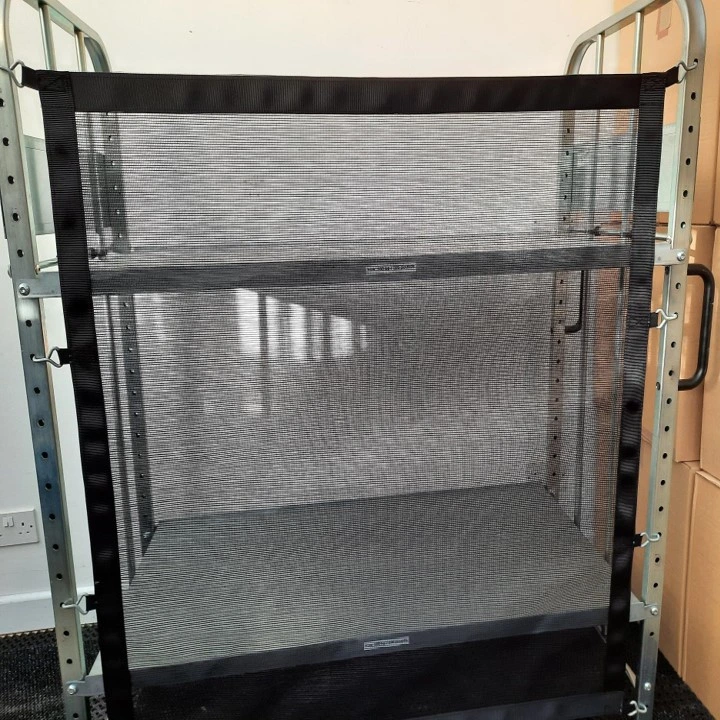

Palband designed and delivered a custom reusable stillage side system, developed specifically for the unique challenges of flat-packed furniture logistics.

- Durability First: Each unit features robust construction, with integrated metal reinforcement to withstand repeated use and protect contents during long-haul transportation.

- Secure and Reliable Fit: The reusable sides ensure consistent load containment—no variation in application, no risk of under-securing. This dramatically reduced movement during transit and virtually eliminated damage caused by shifting loads.

- Sustainability Impact: By removing the need for shrink wrap, the company cut down on hundreds of tonnes of plastic waste annually—supporting their ESG goals and improving their environmental footprint.

The Results

- Plastic waste reduced by over 90% on stillage-wrapped shipments

- Significant reduction in product damage, with a notable drop in customer complaints and returns

- Improved efficiency during loading and unloading, thanks to the simplicity and uniformity of the reusable system

- ROI achieved within the first 12 months, with long-term savings projected across all operational regions

“Palband’s reusable stillage sides have helped us cut plastic waste and reduce product damage during transport. A simple, effective solution that’s made a big difference.”

Logistics Manager, Multinational Furniture Company